Huawei implemented the project in Thailand in partnership with Midea, AIS, and China Unicom.

Chinese vendor Huawei claims to have jointly built Southeast Asia’s first fully 5G connected factory together with electronics maker Midea Group, Thai telecommunications company AIS and Chinese telecommunications operator China Unicom.

Huawei said the project takes advantage of the 5G network coverage of Midea Industrial Park in Chonburi, Thailand, and its 5G advanced industrial Internet platform, and has already seamlessly connected each production stage in the facility through 5G terminals, speeding up the operation of machines.

The vendor also explained that dedicated 5G private networks are being deployed to support factory operational requirements and leverage intelligent industrial applications, facilitating manufacturing scenarios and interconnecting each production line.

Huawei said the combination of massive connectivity and high reliability provided by 5G networks will enable real-time monitoring and analysis of production devices, and continuous data collection and analysis will optimize equipment utilization, reduce downtime, and improve overall equipment capacity.

The Chinese vendor also explained that with 5G technology, automated guided vehicles (AGVs) have undergone a paradigm shift, moving beyond pre-set routes and physical markers for navigation. Dynamic path planning and real-time environmental data analysis increase flexibility and adaptability, greatly improving operational efficiency in complex factory environments, the vendor said.

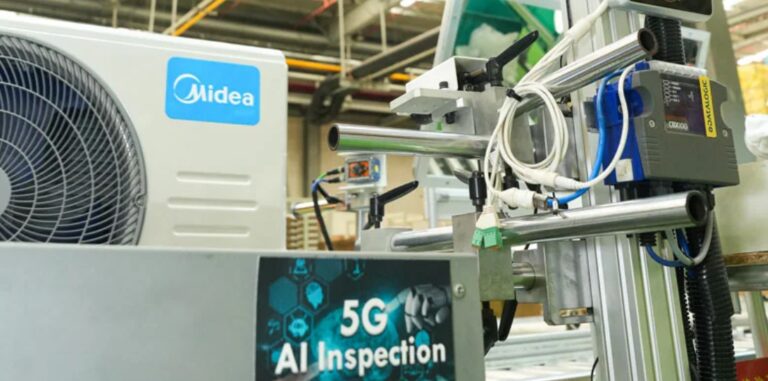

The Thailand factory also offers 5G AI inspection to minimize operation errors during the production stage.

Workers will also be able to remotely control the robotic arm via their 5G smartphones, eliminating the need for dangerous manual intervention in the production process, Huawei added.

The factory also has a 5G “operating room” equipped with 5G technology to simulate and test outdoor compressor conditions to ensure efficient and reliable operation.

Phupa Akavipat, Acting Chief Corporate Business Officer at Advanced Info Services (AIS), said: “Compared to other technologies, 5G is the only technology that enables network coverage of over 160,000 square meters covering three production plants. AIS will continue to focus on driving innovation and helping manufacturers around the world replicate their smart factory set-ups in Thailand.”

“We have seen that 5G has played a key role in driving industrial transformation. The manufacturing industry shows great potential for development and transformation with the introduction of 5G technology. Huawei remains committed to working with industrial customers, carriers, and partners to create business value from 5G,” said Woragarn Likitdechasakdi, CTO of Huawei Thailand.

“To achieve this goal, we will actively engage with customers to understand their digital strategies. By taking a closer look at their production processes and identifying their specific needs, we aim to share valuable experience and best practices to accelerate the adoption of 5G for intelligent manufacturing upgrades,” the Huawei executive added.