Taichung, August 21, 2024 Taiwan, 2020 /PRNewswire/ — microSHIFT cooperated with Taiwan Smart Electric Bicycle Association (TSEBA) to hold the Bicycle Gear Shift System 5G Smart Production Line Innovative Application Project Presentation at Taichung GIS Convention Center. Participating companies included FlexLink, Inventec, NewWave, as well as dozens of bicycle supply chain manufacturers in Taiwan. Central Taiwan region.

With the support of TSEBA, microSHIFT applied for moda’s 5G innovation project and completed it in nine months. Photo courtesy of microSHIFT.

Since 2023, the Ministry of Digital Affairs’ Digital Industry Bureau (MODA) has been actively cooperating with public institutions to promote the application and development of 5G private networks in various industries, aiming to enhance industrial competitiveness through technological innovation. MODA supports these efforts with corresponding policies, actively promotes industry-academia collaboration, and provides funding and technical assistance. This comprehensive support enables industries to rapidly integrate 5G technology and accelerate their upgrading and transformation. Under the guidance of the Digital Industry Bureau, Taiwanese Microshift We are partnering with FlexLink, Inventec and NewWave to develop 5G application areas through the “5G Innovation Application Project”, accelerating the speed of smart transformation.

The combination of 5G and AI will enhance manufacturing and provide solutions for industry upgrading and transformation.

Thompson Xu, Secretary General of TSEBA, said, “5G smart factories can solve the problem of labor shortage in the manufacturing industry. The integrated online and offline production model can collect a variety of production data in real time, which enables flexible production with small batches and diverse options, and uses AI for analysis to further optimize production efficiency and yield. It can realize cost and performance optimization of smart factories, and eventually evolve into an AI production platform and manufacturing base. The completion of Microshift’s 5G smart production line innovative application project sets a model. We hope that all members of the association will upgrade intelligently, enhance their competitiveness, and continue to prosper.” TaiwanTo become a top-class excellent company Taiwan“

Founded 25 years ago, microSHIFT is the world’s third largest manufacturer of bicycle gear systems. North America, EuropeCentral and south americaand AsiaIts customers include famous bicycle brands such as Decathlon, Giant, and Merida. ChinaR&D centre and manufacturing base Taiwan Luxury Brand and Market Development Center united states of america.

Smart manufacturing enables flexible production, optimizes efficiency and strengthens business resilience.

CEO William Chen Jean-Jacob Co., Ltd., CEO of microSHIFT, said: “Given the trend of 5G smart manufacturing and AI, our company saw an opportunity to start a digital transformation project. microSHIFT is the first domestic company to participate in the government’s 5G dedicated network innovation application popularization project and has successfully built a 5G smart production line for bicycle gear systems. We have completed the deployment of 5G dedicated network equipment, including applications such as manufacturing execution system (MES), Internet of Things (IoT), advanced planning and scheduling (APS), and real-time equipment health prediction and diagnosis. In addition, we are also working on the security planning and safety verification of 5G networks.”

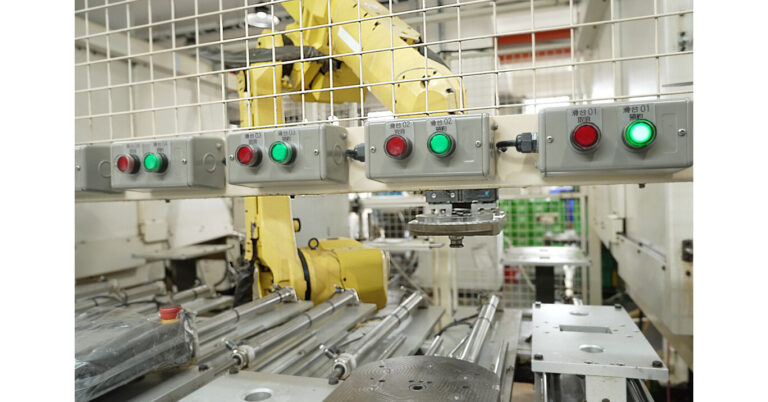

CEO William Chen He explained that the application site is located in the CNC processing area, where 5G equipment and two small base stations are installed. With the cooperation of Inventec, 33 CNC and plastic injection molding machines are networked and equipment health predictive diagnosis is carried out. Taking advantage of the characteristics of 5G private network such as high bandwidth, low latency and multiple connections, data is acquired in real time and a tool wear database is built. Through AI training model, a prediction module is developed that issues warnings before tool abnormalities occur, preventing the production of defective products and reducing operational efficiency losses. In addition, the mobile reporting system uses 5G to transmit information, significantly reducing the time spent on paper-based processes and lowering error rates. The returned information is linked to Siemens’ smart scheduling system OPCENTER, which can flexibly adjust work instructions in real time and improve order fulfillment rates.

Leveraging the high bandwidth, low latency and multi-connectivity capabilities of 5G private networks, microSHIFT has enabled diverse applications, including manufacturing execution systems (MES), Internet of Things (IoT), advanced planning and scheduling (APS), and real-time equipment condition prediction and diagnosis. These advances have further improved production efficiency and management effectiveness. Delivery lead times have been shortened by 15 days, order fulfillment rates have increased by 10%, material availability rates have improved by 10%, and CNC machine utilization rates have increased by 15%. It is expected to significantly reduce labor costs and improve equipment maintenance forecasts, while simultaneously increasing product profit margins and overall revenue.

Source: Taiwan Smart Electric Bike Association (TSEBA)