- 5G mmWave first commercially available to industrial customers

- Use of 26 GHz mmWave 5G frequencies

- Low latency and data rates of 4 Gigabit and above

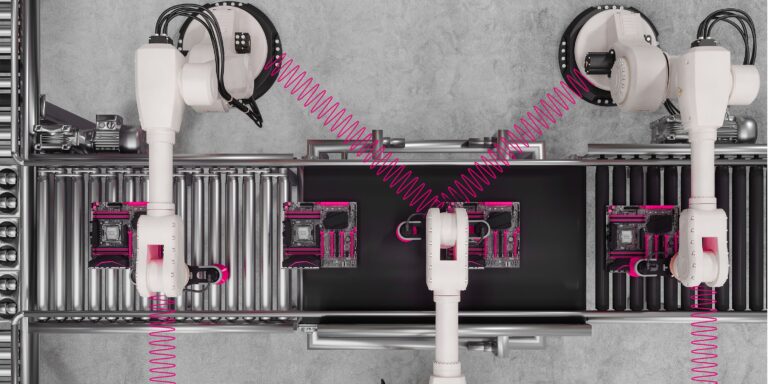

Deutsche Telekom has successfully tested 5G frequencies in the millimeter wave (mmWave) range at 26 gigahertz (GHz) for industrial use for the first time and is now commercially available for industrial customers. For the customer Ger4tech Mechatronik Center, autonomous industrial machines and robots were networked with the router in the 5G campus environment of the Werner von Siemens Center for Industrial Science in Berlin. In addition to 5G standalone in the 3.7 GHz industrial spectrum, the router also supports the so-called mmWave spectrum for the first time. With low latency of 3-4 ms RTT (round trip time) and data rates of more than 4 gigabits per second for download and more than 2 gigabits for upload, mmWave has great potential for data-intensive applications in manufacturing. The 5G mmWave communication is enabled by Telit Cinterion, a global end-to-end IoT solution provider.

Focus on uploads, not downloads

Customers have already deployed 5G campus networks in the mid-band for many industrial applications, but can now exploit their potential by using 5G mmWave for additional applications. Machines collect countless terabytes of data, which are then uploaded to the cloud for analysis, enabling a wide range of new use cases, especially in the field of artificial intelligence. 5G mmWave plays an increasingly important role in wireless communication technology, imaging, and more. It is characterized by a short coverage range and high bandwidth and speed. It has great potential for developments within 5G campus networks, as well as applications in the fields of autonomous vehicles and manufacturing. A special feature of mmWave is its ability to transmit large amounts of data in real time. The frequency spectrum around 26 GHz is only allocated by the German Federal Network Agency to interested parties. It can currently only be used for local applications.

“In the age of artificial intelligence, it is crucial for our industrial customers to be able to upload data from their machines and make it available and analyzeable in real time,” explains Klaus Werner, Managing Director Business Customers at Telekom Deutschland GmbH. “This is the only way companies can implement AI applications wisely and efficiently to deliver significant benefits to their business.”

“We are giving our customers access to unparalleled levels of efficiency, productivity and innovation. Seamlessly integrating 5G mmWave into their operations will enable every device and process to connect at an unprecedented scale,” said Marco Contento, vice president of mobile broadband product management at Telit Cinterion. “Together, we are paving the way for industries to streamline operations, predict maintenance needs and realize the many possibilities of the future.”

Autonomous Work Robots at the Werner von Siemens Center

The Werner von Siemens Center’s 5G Standalone Campus Network operates separately from the Telekom’s public mobile network. The entire infrastructure is from Ericsson, from antennas and active systems technology to the core network. Based on this network, a fleet of autonomous driving and handling robots runs for various use cases at the center. To control the robots, a 5G Standalone network is often sufficient. 5G mmWave comes into play when communication and data transmission requirements increase, i.e. to solve more complex tasks. For example, in computer vision applications, a robot receives an order and checks whether the ordered items are available on the way to its next destination. In case of discrepancies, the items are immediately reordered.

In addition to these, many other scenarios are planned at the Werner von Siemens Center, where industry, research institutes (including the Technical University Berlin and Fraunhofer), small and medium-sized enterprises and start-ups are working on practical solutions for companies, including autonomous production logistics and other challenges in industrial manufacturing.