Spray-applied MXene antennas developed by Drexel researchers have proven to withstand the antennas that power modern telecommunications devices.

The new antenna, which is thin enough to be sprayed into place, is also robust enough to provide strong signals in the bandwidths used by fifth-generation (5G) mobile devices. Drexel University researchers recently reported performance results for an antenna made from a new type of two-dimensional material called MXene, which has the potential to impact mobile, wearable, and connected “Internet of Things” (IoT) technologies. There is sex.

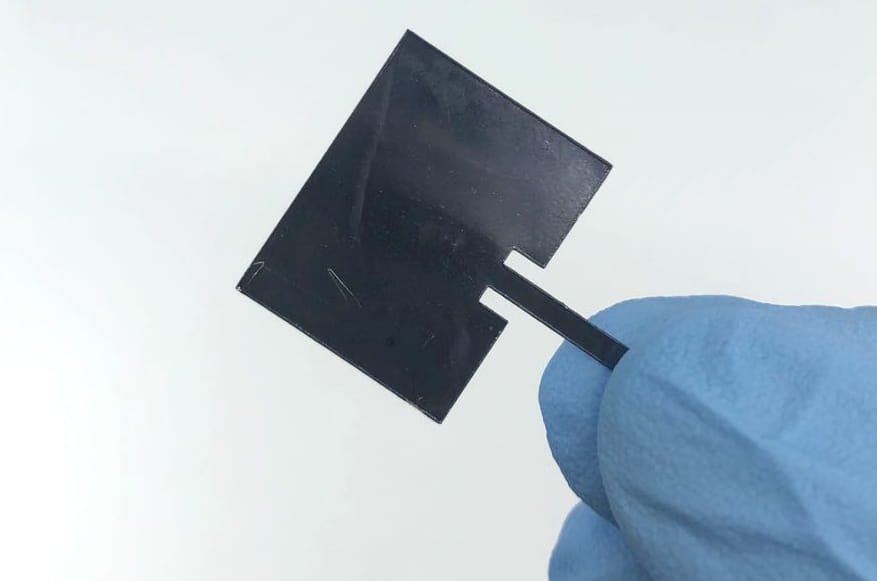

The MXene antenna is In development for over 2 years at Drexelalready has performance similar to the copper antennas found in most mobile devices on the market today, but with the advantage of being only a fraction of the thickness and weight.

“The combination of communication performance and extreme thinness, flexibility and durability sets a new standard in antenna technology,” he said. Dr. Yuri Gogotsidistinguished university and Bach professor materials science and engineering inside drexel Faculty of Engineeringis the lead author of a paper on MXene antennas recently published in the journal advanced materials. “Copper antennas have long been the best in terms of performance, but their physical limitations have prevented connected and mobile technologies from making the huge advances many expected. MXene antennas have the potential to play an effective role in the development of IoT technologies due to their unique properties.”

Mobile carriers are working to deploy 5G technology, which could leverage underutilized parts of the communications spectrum to enable faster data transmission, but over time the new technology This is likely to be within the standard operating range.

Antennas in future devices will not only need to achieve performance capabilities, but will also need to be able to operate successfully in a variety of environments beyond the circuit boards of phones and computers. According to Gogotsi, MXene can be spray-coated, screen-printed, or inkjet-printed onto almost any substrate and maintains flexibility without sacrificing performance, making it an attractive material for new antennas.

“Typically, copper antenna arrays are manufactured by etching a printed circuit board, but doing this on a flexible substrate is a difficult process,” he said. Dr. Han Meikan,doctor student. AJ Drexel Nanomaterials Institute People who contributed to the research. ” This gives MXene a distinct advantage, as it can be dispersed in water to produce an ink that can be sprayed or printed onto building walls or flexible substrates to create antennas. ”